New requirements: Insulation monitoring for 1000V in grid stations

The degree of electrification in Norway is increasing — including in rural districts, where power grid stations with 1000V are becoming more and more common. Electrification has given rise to a need for common guidelines for the connection process, in particular due to specific documentation requirements imposed by authorities. The guidelines were introduced in RENblad 9116 this summer, and included, among other things, a requirement for insulation monitoring for 1000V in grid stations.

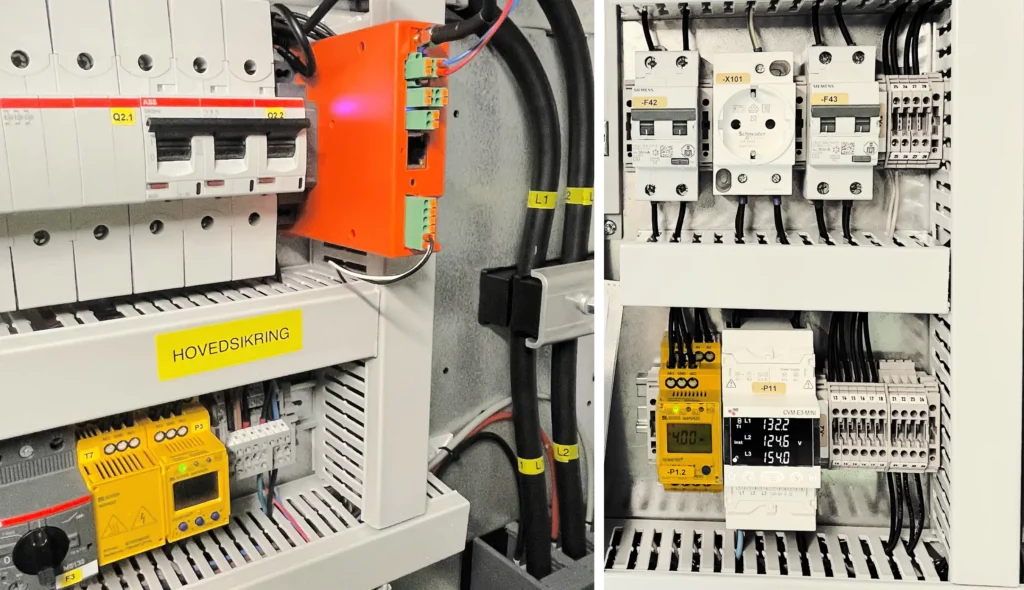

SafeBase has now upgraded its SafeMon Advanced Grid Station Monitoring (ANSO) to include real-time insulation monitoring for 1000V in grid stations.

“The electrification of fish farming installations in particular, but also general electrification in rural districts and on farm installations affected by long distances, has made 1000V systems more and more common. When REN 9116 came, with separate requirements for 1000V systems, we knew we had to upgrade SafeMon immediately, says Frode Johansen in SafeBase.

This is insulation monitoring from SafeBase

Insulation monitoring from SafeBase is a complete insulation resistance measurement between phase and ground for 1000V IT power grids in accordance with REN 9116 and regulatory requirements — a turnkey solution within SafeMon. The solution is delivered already wired on a mounting plate, or connected in the grid station.

“This is normally used where 230V is transformed up to 1000V for overhead transfers and then back down to 230V for end customer distribution. The solution can also be delivered with an on-the-ground transformer station, which does not require service mast access. That way, the annual inspection can be performed by a single technician — which makes the work even more cost-efficient, says Johansen.

SafeBase insulation monitoring complies with:

- ground fault detection for 230V IT power grids

- neutral grounding monitoring

- complete insulation monitoring for 1000V line spans

In addition, you also get all the other benefits of real-time monitoring from SafeBase. Grid analyzer is included as standard — for real-time monitoring of current, voltage, load, THD-measurements, and a wide range of other parameters.

This is RENblad 9116: The data sheet provides an overview of system voltage 1000V. The data sheet specifies which voltage system that should be used, how the transformer and the rest of the system is protected, 1000V measurements, where and how to interface with the customer, and when 1000V can be an option.

Watch REN’s webinar on the new requirements (external link) >>

Installing SafeMon in all grid stations

BKK Nett has already installed SafeMon and 1000V insulation monitoring in two grid stations, as a pilot project before the solution is rolled out to all grid stations. They have also installed a couple hundred units on 230V grid stations.

“In the next year, we will be installing 1000V insulation monitoring in many grid stations. The benefit of SafeMon is that we can easily add insulation monitoring to already existing installations for 230V ground fault monitoring, says Helge Sunde in BKK Nett.

Sunde is a trained electrician and technician. He is currently working as a consultant and project planner in BKK Nett.

“Recently, we have already installed grid analyzers in our grid stations, often Micro Matic CVM-Mini. So now we’re only talking about an hour’s work out on the station and a 30-cm cable between SafeMon and the analyzer. In older grid stations, we are ordering prefabricated cabinets, which we install on the wall. The installation of these often takes several hours.”

Very happy with the pilot project

Sunde explains that the pilot project has been a huge success so far.

“We struggled a bit in the beginning with poor communication between instruments, due to a supplier-specific address on one sensor, but SafeBase solved this for us immediately. As soon as the solution was up and running, we tested it by introducing a ground fault in the system. It detected this and notified SafeMon immediately, says Sunde.

“We are also excited to find out how many things we can use these data for later. The fact that we can monitor current, power and voltage, as well as pull up accurate data from the past 30 seconds, the last hour, yesterday, last week or last year; I have a feeling this is going to be a key project planning tool for us going forward, Sunde says.

Major benefits of real-time data

The real-time monitoring provided by SafeMon is a very good tool for grid companies, providing them access to information about minor errors and the capacity of the grid in real time, so they can prevent major errors down the line.

“Initially, these requirements mean considerable investments for us power grid companies, as we are having to upgrade our installations in all grid stations. But if you only consider the cost — and not the investment — you are not thinking far enough ahead.”

“The savings in unnecessary travel times are significant. Even now, with just the pilot project, we can see that data from SafeMon make our activities significantly more cost-efficient. With SafeMon, we don’t have to go out to the stations every time we suspect faults or problems. We can also monitor when repetitive ground faults tend to happen, so that we can have technicians on site when the faults actually occur. Down the line, when we have monitoring in every grid station, we only have to move out to the site gwhen there is actually something wrong, Sunde happily concludes.